-

How to Disable Heating in Ultrasonic Cleaners: A Comprehensive Guide

How to Disable Heating in Ultrasonic Cleaners: A Comprehensive Guide

I. Reasons to Disable Heating 1. Application Scenarios Temperature-sensitive materials: Plastics (deformation risk above 50°C) Biological samples (prot

-

Why Can't Ultrasonic Cleaners Use Thin Steel Sheets? - An Engineering Analysis of Resonance Principles and Material Selection

Why Can't Ultrasonic Cleaners Use Thin Steel Sheets? - An Engineering Analysis of Resonance Principles and Material Selection

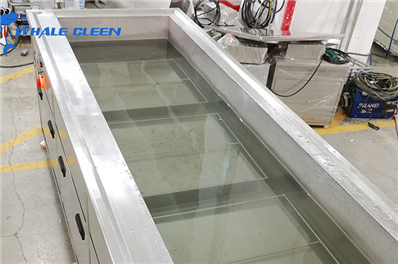

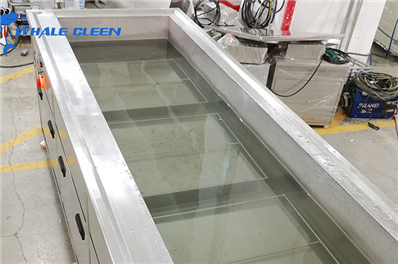

In the field of industrial manufacturing and equipment material selection, a fundamental principle is: "The right material for the right application." For ultrasonic cleaners, the choice of material for their core working component—the tank that

-

Prolonging the Service Life of Ultrasonic Cleaning Machines: Expert Maintenance Strategies for Cleaning Tools

Prolonging the Service Life of Ultrasonic Cleaning Machines: Expert Maintenance Strategies for Cleaning Tools

Ultrasonic cleaning machines play a crucial role in various industries, offering efficient and precise cleaning solutions. To ensure their optimal performance and prolong their service life, a series of maintenance measures need to be implemented. This ar

-

Elevating Industrial Seal Performance and Lifespan through Ultrasonic Cleaning

Elevating Industrial Seal Performance and Lifespan through Ultrasonic Cleaning

Cleaning industrial seals is a pivotal process that holds the key to improving their sealing performance and overall lifespan. The utilization of ultrasonic cleaning machines to eliminate contaminants and particles from the metal surfaces of industrial se

-

Ensuring Equipment Safety: Ultrasonic Cleaning for Metal Safety Valves

Ensuring Equipment Safety: Ultrasonic Cleaning for Metal Safety Valves

Cleaning metal safety valves is crucial to ensure the proper functioning and safety performance of industrial equipment. Safety valves play a critical role in industrial processes, as they automatically release excess pressure when system pressures exceed

-

Ultrasonic Cleaning for Metal Printing Machine Components: Ensuring Print Quality and Equipment Reliability

Ultrasonic Cleaning for Metal Printing Machine Components: Ensuring Print Quality and Equipment Reliability

Cleaning metal printing machine components is an essential step to ensure printing quality and equipment reliability. During the printing process, metal parts can accumulate ink residues, oil, and other impurities, which can negatively impact print qualit

-

Advancements and Applications of Ultrasonic Cleaning Machines in the Defense Industry

Advancements and Applications of Ultrasonic Cleaning Machines in the Defense Industry

Ultrasonic cleaning machines have found widespread applications in the defense industry, providing efficient and reliable solutions for cleaning and maintenance of military equipment. Their non-contact, high-performance cleaning capabilities make them ide

-

Why Do Ultrasonic Cleaners Use 28kHz Frequency? The Science Behind the Power Setting

Why Do Ultrasonic Cleaners Use 28kHz Frequency? The Science Behind the Power Setting

When shopping for an ultrasonic cleaner, you'll quickly encounter a key specification: frequency. Among the most common options is28kHz. This number isn't arbitrary; it represents a deliberate engineering choice that makes this frequency a powerho

-

Why Do Ultrasonic Cleaners Have Multiple Cleaning Stages? The Science Behind the Process

Why Do Ultrasonic Cleaners Have Multiple Cleaning Stages? The Science Behind the Process

Ultrasonic cleaners are widely used in industries such as manufacturing, healthcare, jewelry, and automotive for their ability to clean intricate items with precision. However, many users wonder why these machines often involve multiple cleaning stages in

-

Why Did the Ultrasonic Cleaner Sound Suddenly Become Louder? Causes and Solutions

Why Did the Ultrasonic Cleaner Sound Suddenly Become Louder? Causes and Solutions

Ultrasonic cleaners are renowned for their efficiency in cleaning delicate items, from jewelry to medical instruments. However, when the device’s sound suddenly becomes louder than usual, it can be both alarming and indicative of an underlying issue. Unde

-

Ultrasonic Cleaner Lid Necessity: Safety, Efficiency, and Performance Explained

Ultrasonic Cleaner Lid Necessity: Safety, Efficiency, and Performance Explained

When you unbox your newultrasonic cleaner, the included lid might seem like a simple accessory—perhaps even an optional one. Many users are tempted to operate the machine without it, thinking it allows for better visibility or easier access. However, this

-

Why Ultrasonic Cleaners Must Not Have Low Water? The Critical Role of Water Level Explained

Why Ultrasonic Cleaners Must Not Have Low Water? The Critical Role of Water Level Explained

For anyone who owns an ultrasonic cleaner, the instruction to "fill the tank with adequate water" is as fundamental as it gets. Yet, in moments of haste or curiosity, you might wonder what would happen if you ran it with less water than recommen

How to Disable Heating in Ultrasonic Cleaners: A Comprehensive Guide

How to Disable Heating in Ultrasonic Cleaners: A Comprehensive Guide

Why Can't Ultrasonic Cleaners Use Thin Steel Sheets? - An Engineering Analysis of Resonance Principles and Material Selection

Why Can't Ultrasonic Cleaners Use Thin Steel Sheets? - An Engineering Analysis of Resonance Principles and Material Selection

Prolonging the Service Life of Ultrasonic Cleaning Machines: Expert Maintenance Strategies for Cleaning Tools

Prolonging the Service Life of Ultrasonic Cleaning Machines: Expert Maintenance Strategies for Cleaning Tools

Elevating Industrial Seal Performance and Lifespan through Ultrasonic Cleaning

Elevating Industrial Seal Performance and Lifespan through Ultrasonic Cleaning

Ensuring Equipment Safety: Ultrasonic Cleaning for Metal Safety Valves

Ensuring Equipment Safety: Ultrasonic Cleaning for Metal Safety Valves

Ultrasonic Cleaning for Metal Printing Machine Components: Ensuring Print Quality and Equipment Reliability

Ultrasonic Cleaning for Metal Printing Machine Components: Ensuring Print Quality and Equipment Reliability

Advancements and Applications of Ultrasonic Cleaning Machines in the Defense Industry

Advancements and Applications of Ultrasonic Cleaning Machines in the Defense Industry

Why Do Ultrasonic Cleaners Use 28kHz Frequency? The Science Behind the Power Setting

Why Do Ultrasonic Cleaners Use 28kHz Frequency? The Science Behind the Power Setting

Why Do Ultrasonic Cleaners Have Multiple Cleaning Stages? The Science Behind the Process

Why Do Ultrasonic Cleaners Have Multiple Cleaning Stages? The Science Behind the Process

Why Did the Ultrasonic Cleaner Sound Suddenly Become Louder? Causes and Solutions

Why Did the Ultrasonic Cleaner Sound Suddenly Become Louder? Causes and Solutions

Ultrasonic Cleaner Lid Necessity: Safety, Efficiency, and Performance Explained

Ultrasonic Cleaner Lid Necessity: Safety, Efficiency, and Performance Explained

Why Ultrasonic Cleaners Must Not Have Low Water? The Critical Role of Water Level Explained

Why Ultrasonic Cleaners Must Not Have Low Water? The Critical Role of Water Level Explained